Granitgard

Give Termites the Flick with Granitgard!

Granitgard is a natural, non-toxic termite management system that offers long-life protection from termites. It uses durable materials to form a management system that provides a safe and effective alternative to the use of dangerous residual poisons or less sturdy physical termite management systems.

Cost effective and easy to install, Granitgard is a premium physical termite management system that exceeds statutory building requirements. Granitgard also comes with a 50 year warranty*

360° Protection – Areas to Protect

Protecting Home Builds Against Termite Damage

Subterranean termite (white ant) damage is a significant concern throughout mainland Australia. Each year the cost of repairing termite affected timber amounts to tens of millions of dollars. Infestation in some areas is greater than one in five properties. As a result, the Building Code of Australia makes it compulsory to provide a termite management system to protect structural timber in new buildings. To leave any timber or timber product unprotected is a real risk.

Granitgard for Perimeters

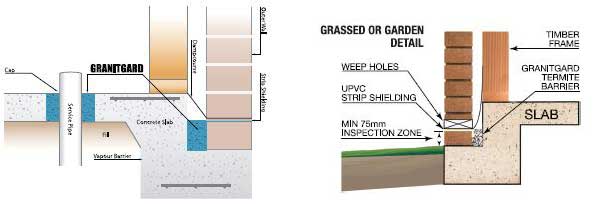

Granitgard is placed around building perimeters, providing a flexible, long-life termite management system for these highly vulnerable areas.

Granitgard for Pipes

By surrounding each pipe with a collar of Granitgard, this common termite access point is blocked. The Granitgard remains flexible and allows for independent ground, slab and pipe movement.

Granitgard for Construction Joints and Retaining Walls

These design features are not incorporated into all buildings but where they are termites often use them for access. Granitgard installers offer a number of approved treatment methods to protect these hidden areas.

Developed With CSIRO

Developed over 15 years in conjunction with CSIRO and used successfully in more than 150,000 buildings across Australia. Granitgard complies with Australian Standards, the Building Code of Australia (Nationally Certified with Codemark).

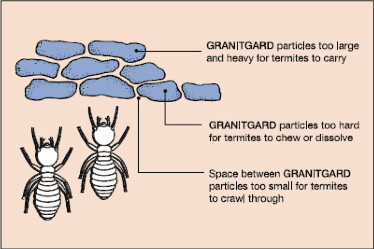

Extensive laboratory work and field trials throughout Australia have enabled the CSIRO to determine the precise specifications for the size, shape and composition of the stone barrier. Each batch of Granitgard is graded to these specifications to ensure impenetrability and tested for compliance in registered NATA laboratories.

Caring for the Environment

The natural stone material used to make Granitgard is a by-product of concrete and road sealing aggregate crushing. That portion of quarry output which is too fine for other products is re-processed to make Granitgard. Crushing, screening, vacuuming, packaging and delivering the volume of Granitgard required to treat one home uses very little energy and has low environmental impact. There are no chemicals added to Granitgard. Installing Granitgard in a building actually reduces that structure’s energy demand because Granitgard also helps to insulate the underside and perimeter of concrete slabs.

How Granitgard Protects New Buildings

New buildings can be protected from termites with one treatment of natural, non-toxic; Granitgard graded stone physical termite management system material. This treatment is easily applied during construction and could save the building from destruction.

Granitgards flexibility means that it will remain effective when the buildings’ service connections, footings, foundations and walls expand and contract. Granitgard allows building components to move independently without breaking the termite management system or cracking walls, footings and pipes.

Granitgard termite management system does not require replenishment or repairs unless the barrier has been disturbed, during renovations or plumbing repairs, for example. In situations such as these, contaminated graded stone should be removed and the termite management system topped up to the appropriate level with fresh stone.

Explore Our Range of pre-construction Termite Management Systems